JSWmetal hot melt adhesive film solidifies crosslinking to form a stable chemical structure. Recently, JSW learned at the Exhibition Center of Sunway International High-tech Park in Taiwan that the newly developed metal hot melt adhesive film and related equipment have been successfully applied to the key projects of mobile phones, computers and monitors of many world-renowned companies, including digital products. Become one of the few suppliers that can provide metal hot melt adhesive film and supporting dispensing and curing equipment.

The above is a brief introduction to metal hot melt adhesive film. If you need more information, please visit the information download WINOOW of our official website to download. The following is informal information about metal hot melt adhesive film for reference only.

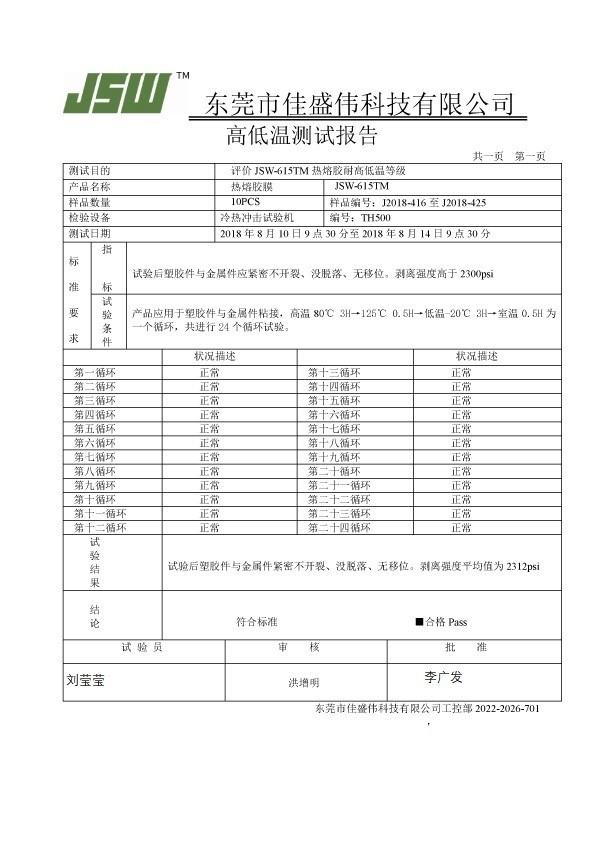

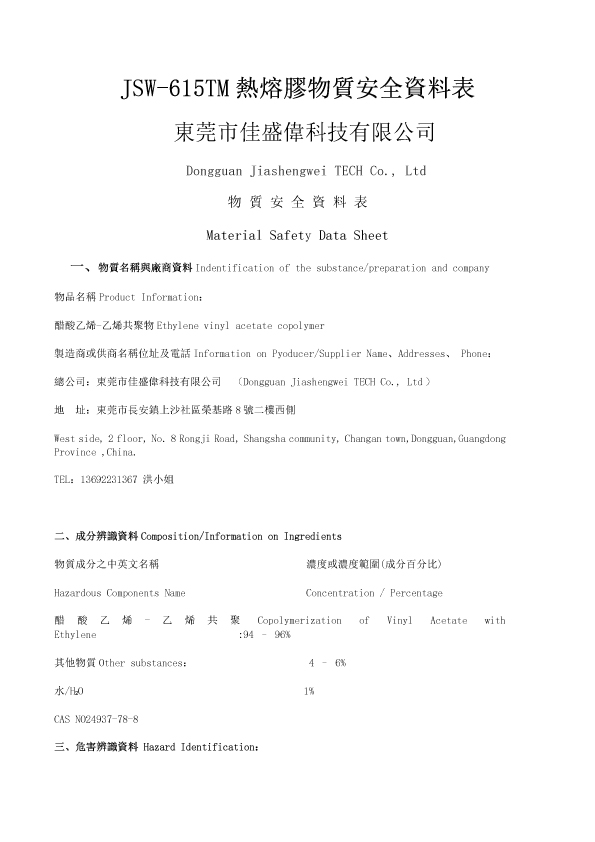

JSW- sizing convenient, low melting point, 110℃ sizing. Widely used as a bonding solution for narrow frames of mobile phones and tablet computers, metal hot melt adhesive film has excellent weather resistance: it is irreversible after being brided, so it is not subject to creep and brittle due to changes in ambient temperature. Modified solid metal hot melt adhesive film is a kind of cross-linked structural adhesive with high bonding strength. It has good fluidity when heated and is convenient for coating. With heating fast melting, cooling fast (about 4s) can achieve high strength bonding characteristics. metal hot melt adhesive film can meet the bonding requirements of structural components of mobile electronic products. High toughness, strong initial adhesion, strong permeability and affinity metal hot melt adhesive film, adhesive strength is 40% ~ 60% higher than other adhesives under the same conditions, reducing the use of adhesives.

The above is a brief introduction to metal hot melt adhesive film. If you need more information, please visit the information download WINOOW of our official website to download. The following is informal information about metal hot melt adhesive film for reference only.

JSW metal hot melt adhesive film,The physical properties listed are typical values and are not to be considered as specifications. Our suggestions for use are based on tests we believe to be reliable. However, the purchaser must carry out their own tests to determine the suitability of the product for their internal use. Information is given in good faith, but without warranty.

JSW- JSW plastic hot melt adhesive film

instructions: Please empty a small section of glue before dispensing. Heat melt the JSW3542 JSW615 hot melt adhesive at a constant temperature of 110 ℃, apply the adhesive to the part to be bonded with the dispensing equipment, complete the bonding within 2 minutes, and maintain the pressure in the fixed tool for 10-20 minutes before moving to the next POSTTTION. It is not recommended to heat eachJSW plastic hot melt adhesive film

continuously for more than three hours. The same

JSW plastic hot melt adhesive film

cannot be heated three times. Heating for a long time will make the rear part of the rubber tube touch the air temperature and form a crust, which can be pierced to reduce the glue pressure.

As the pillar industry of digital adhesive, JSW

JSW plastic hot melt adhesive filmhas maintained a good development trend. However, with the contraction of handheld industry and the increase of labor cost in the future, the road of traditional adhesive manufacturing industry relying on human development has become narrower and narrower. At the same time, the new products represented byJSW plastic hot melt adhesive film are bringing innovative industrial reform to the traditional assembly manufacturing and production methods ofJSW plastic hot melt adhesive filmdispensing process and other related industries. Industry analysts pointed out that intelligent dispensing technology and control technology makeJSW plastic hot melt adhesive film system production as a whole, and the high-level

JSW plastic hot melt adhesive filmtechnology for the purpose of expanding or replacing mental labor is an important technical basis for the realization of assembly scale chemical plants. The development of China's electronic manufacturing industry in the new era and form must be accompanied by intelligence and automation.