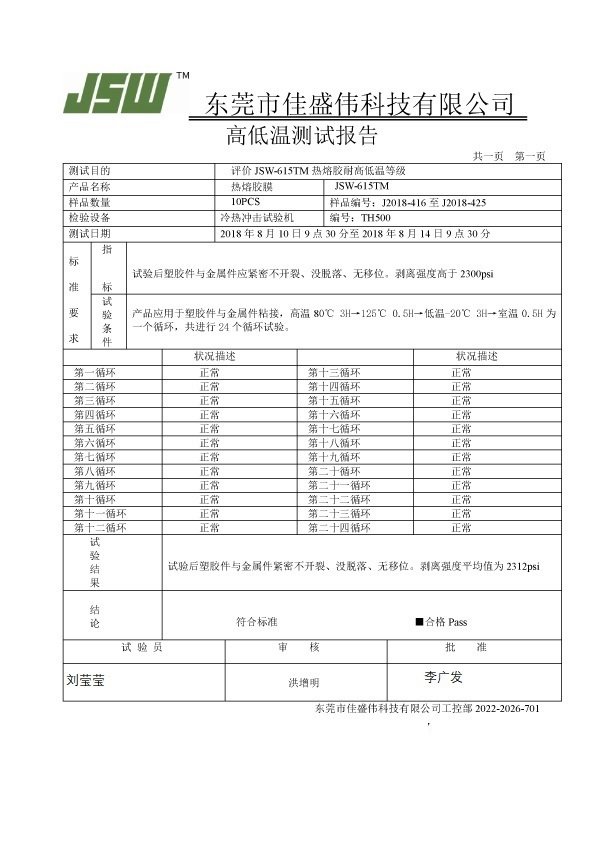

JSW- Anti-JSW Thermo-Bond Film 615 has good impact uniformity. It has good bonding properties with various substrates. Product characteristics: Good bonding: can be bonded to a variety of substrates (such as PP, PC, ABS, PMMA, metal, glass and other TP lens bonding), pure solid, non-corrosive. Good high and low temperature resistance, JSW Thermo-Bond Film 615 can work in -25℃ ~ 95℃ environment for a long time. Excellent weather resistance, sealing, corrosion resistance, aging resistance, creep resistance, temperature shock resistance. Fast initial curing, 10 ~ 20 minutes after gluing can reach the initial curing. JSW Thermo-Bond Film 615 bonding technology is gradually establishing and improving its technical standards and process specifications, and expanding its application range. In particular, the emergence of JSW Thermo-Bond Film 615 technology and nanomaterials is a technological reform, but also an industrial reform. It can be expected that JSW Thermo-Bond Film 615 material will have a significant impact on the modification of adhesives, and the latest research results of JSW adhesives will be achieved.

Thermo-Bond Film 615,When you view products in our store we’ll keep track of them here for you.Thermo-Bond Film 615,Flexible, light-colored, thermoplastic adhesive bonding film that exhibits good adhesion to a variety of substrates. The bonding film is

removable from the release coated paper carrier. Available with 2.5 mil or 4.0 mil adhesive layer.Thermo-Bond Film 615,Oops, no products have been added to this category yet.Equivalment To TThermo-Bond Film 615hermal Hot Melt Adhesive Bonding Film Tape For Metal Bonding,If you’re not seeing your recently viewed products keep in mind your browser or device settings could affect this.

JSW- Thermo-Bond Film 615bonding technology is a technology which is widely used, has unique functions, remarkable economic and social benefits, simple equipment, simple technology and strong practicability. JSW-Thermo-Bond Film 615 is an important part of bonding technology for metal, plastic, PMMA, acrylic, glass, etc. Because Thermo-Bond Film 615 material is mainly used to make all kinds of digital products, such as narrow frame and TP screen bonding, instruments and WINOOWs products with cutting-edge technology, their weatherability has to go through severe and harsh conditions for continuous work. Therefore, Thermo-Bond Film 615 bonding technology not only has a wide application field, but also has a simple technical content and a general process difficulty. It only requires a higher performance than adhesive. Higher.

Thermo-Bond Film 615 manufacturing resources (materials, energy, equipment, tools, capital, technology, information and human resources, etc.) are transformed into industries that can be used and utilized by people andThermo-Bond Film 615 industrial products and consumer products through manufacturing process according to market requirements.Thermo-Bond Film 615 manufacturing industry directly reflects the adhesive productivity level of a country, which is an important factor to distinguish developing countries from developed countries. Thermo-Bond Film 615 manufacturing industry occupies an important share in the national economy of developed countries in the world.

According to the material forms used in production,Thermo-Bond Film 615 manufacturing industry can be divided into discrete manufacturing industry and process manufacturing industry.

Equivalment ToThermo-Bond Film 615 Thermal Hot Melt Adhesive Bonding Film Tape For Metal Bonding

Hot melt adhesive bonding film tape combined with the advantages of film and hot melt technology and excellent performance on many substrates of the fibers, polyolefins, liquid crystal polymer, temperature-Thermo-Bond Film 615,sensitive materials, and metal, providing temporary adhesion to permanently bond ,variety of options.Which can replaceThermo-Bond Film 615hot melt bonding film.