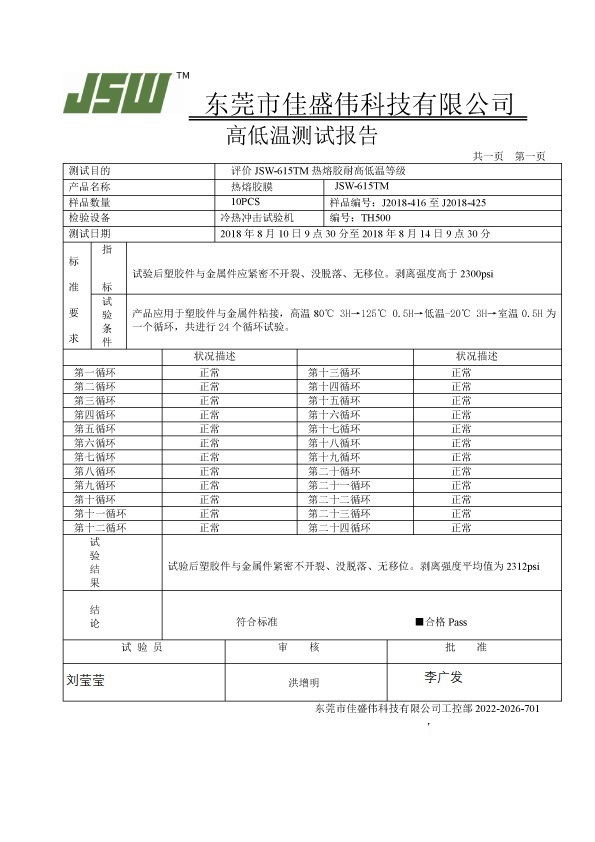

Most of the global producers of Bonding Film 615 will continue to recover from the excess capacity in 2013 and continue to stimulate the growth of electronic product production, in order to significantly boost the global sales growth of TP screen fasteners. It is expected that the industrial Bonding Film 615 industry will maintain a higher development momentum in the future. According to the growth rate from 2011 to 2014, the global sales volume of industrial Bonding Film 615 is expected to be 6 percent per year. It grew by 8% to $8.9 billion in 2016. In 2014, the JSW industry was the largest Bonding Film 615 product supplied to the assembly companies, and it is expected that this product will show the biggest growth point until 2016. Meanwhile, the accelerated growth of mobile phone manufacturing production and digital investment will also promote the growth of Bonding Film 615 usage. Stiff competition from alternative connections, such as adhesives, will not curb sales growth in some market segments of Bonding Film 615.

Developed technology Bonding Film 615 enterprise is still the main supplier of adhesives in the electronics industry. In terms of production, JSW will continue to build factories in Taiwan and other industrial development areas, mainly to take advantage of Bonding Film 615's low cost advantage in these areas to produce high-end products. Taking advantage of the trend of high-end digital industry, JSW has developed higher quality adhesives for electronic applications, making JSW the main supplier of Bonding Film 615. It occupies half of the total market share of the mobile phone industrial accessories, and is expected to become the industrial Bonding Film 615 with the largest demand value in 2016, mainly due to the growth of all kinds of electronic consumer goods with WINOOWs. However, due to the growth of investment in infrastructure construction and the growth of large Bonding Film 615 capital goods production, JSW has significant advantages and will show the fastest growth rate.

The famous JSW Bonding is the application of Bonding Film 615, which has the advantages of quantitative sizing, bonding strength of plastic structure and metal similar structure. Because the energy of a variety of material structures changes in a wide temperature range, Bonding Film 615 can be produced by needle outflow, adhesives and other structural materials co-phase bonding phenomenon. Bonding Film 615 dispensing technology is considered to be the only equipment that can bond products accurately, directly and quantitatively. In the composite structure, the structure characteristics determine the loading mode. Bonding Film 615 bonding technology has successfully determined the bonding POSTTTIONs near the edges of various bonding structures and fully controlled the physical factors that actually affect bonding, such as voids and inadequate wetting. It can not only fully cure, surface treatment and the interface is not contaminated.

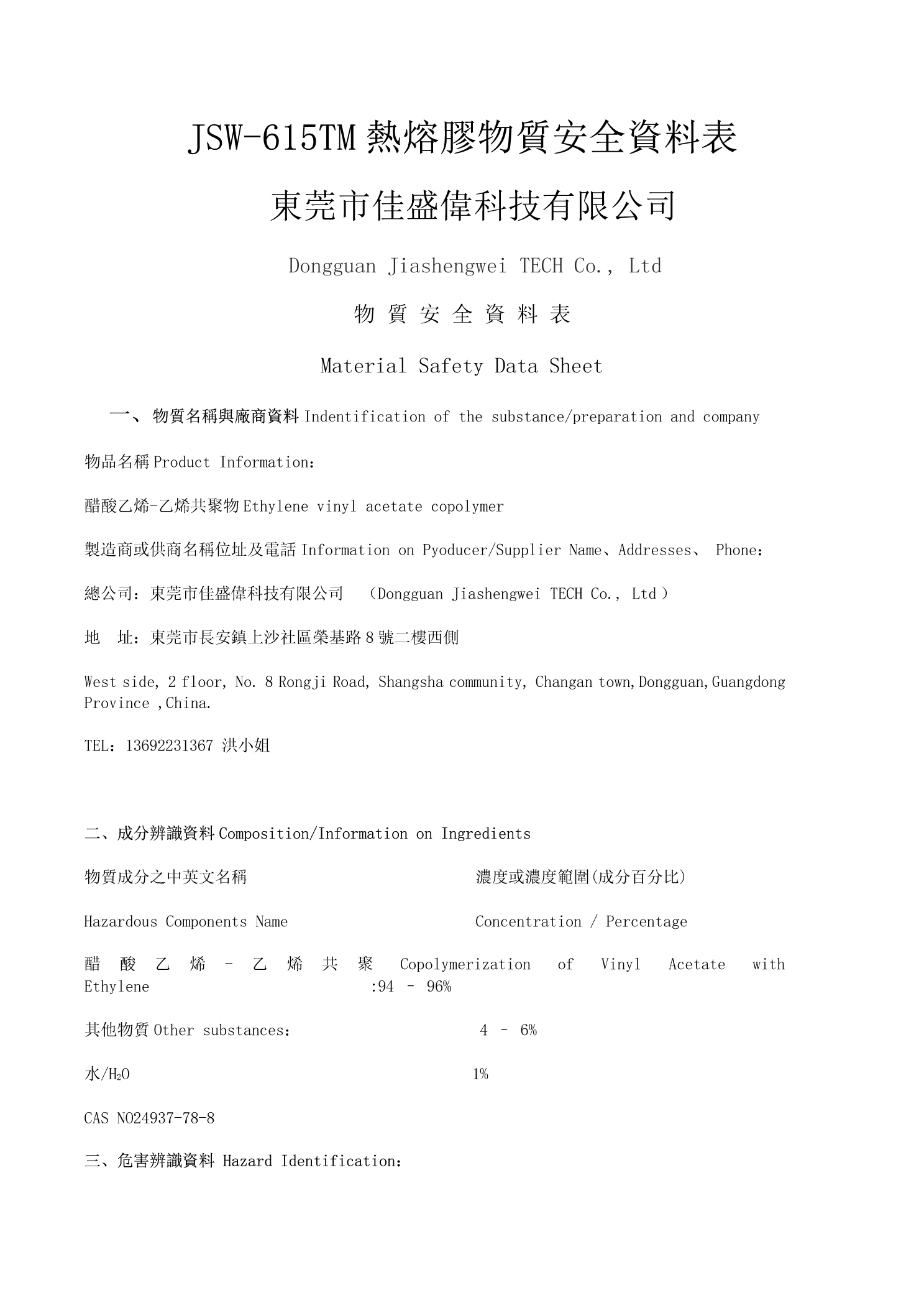

JSW Thermal Bonding Film 615S is a flexible, light colored, thermoplastic adhesive bonding film which exhibits good

Note: Appropriate application equipment can enhance bonding film performance.

for the user’s evaluation in light of the user’s particular purpose and method of application.

The type of equipment used to JSW Thermal Bonding Film (TBF) 615 will depend on the application and on the

type of equipment available for the user. Thin films and flexible substrates can be bonded using a heated roll laminator

where heat and pressure can be varied to suit the application. Larger, thicker substrates can be JSW Thermal Bonding Film 615 bonded using a heated

static press or, in some cases, an autoclave. For applications where a shaped adhesive is to be transferred to a flat or

three-dimensional part, a hot shoe or thermode method may be appropriate.

It is recommended that whatever method of bonding the user chooses, the user should determine the optimum

bonding conditions using the specific substrates involveOne approach to establishing the correct/optimum bonding conditions for a user’s application is to evaluate a series

and more difficult to bond surfaces will require longer times, higher pressures and higher temperatures.

Once the bond is made, the bondline should be allowed to cool somewhat before stress is applied to the bond. Generally,

cooling the bondline below 93°C (200°F) is adequate to allow the bonded parts to be unfixtured/unclamped and handled.

For reference, the following tables show typical bond strengths for bonds made at various temperatures. Such tables

can be used to evaluate optimum bondline temperatures. It is very important to note that this table is valid only for

the specific substrates shown. Varying temperature, pressure, or substrates can affect bond strengths. User should

develop a similar table using the specific substrates involved. d.

Unless an additional warranty is specifically stated on the applicable JSW Thermal Bonding Film 615 product packaging or product literature,

CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY

IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED

WARRANTY OR CONDITION ARISING OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE. If the 3M product

does not conform to this warranty, then the sole and exclusive remedy is, at JSW Thermal Bonding Film 615s option, replacement of the JSW Thermal Bonding Film 615 product

or refund of the purchase price.

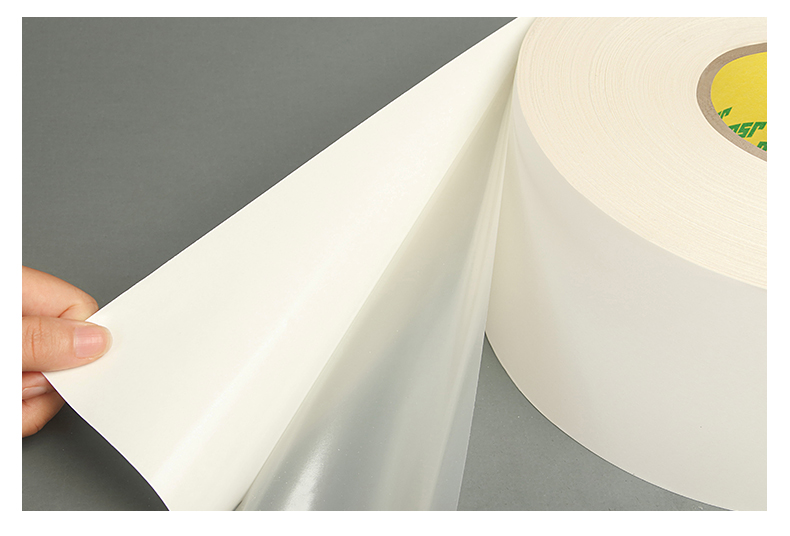

adhesion to a variety of substrates. The bonding film is supplied on a release coated paper liner. JSW 615 Thermal Bonding Film 615S contains,a non-woven scrim reinforcing web that improves handling of the film, and reduces flow of the adhesive during bonding.

of bonding temperatures, for example 121, 135, 149, 163 and 177°C (250, 275, 300, 325 and even 350°F). Time and JSW Thermal Bonding Film 615

pressure will be dictated by the thickness of the substrate and the type of substrate being bonded. Thicker substrates